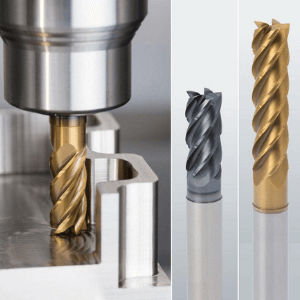

End Mills

technical specification

End Mill Cutter cut material on both the periphery and end simultaneously creating stress since the tool is held only at the spindle. Auto Lathe’s design minimizes deflection and chatter. Facing, slotting and profiling can be accomplished with two, three or four or more flute tools. We provide a complete range of tools in high speed steel and cobalt steel for these operations.

We have more than 20 years of experience in manufacturing metal cutting tools like threading taps, thread gauges, drills, reamers, and others. We try our best to deliver the product as soon as possible.

Whether the job requires an end mill cutter cutting to the center or non-center cutting we have the tool in an extensive range of sizes. When cavity milling is necessary tools with a radius ground on the corner or a ball end mill is recommended. Consistent tool life is assured through constant research into design and the best composition of steel and heat treating methods.